Hand Operated Oil / Grease Pumps

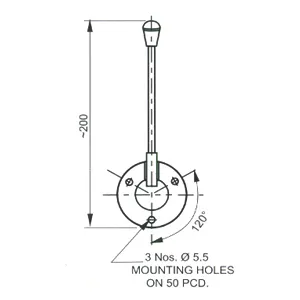

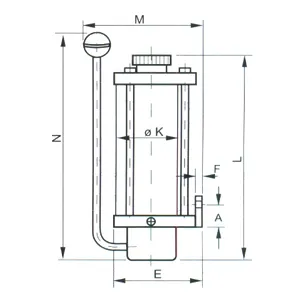

These are Manually Operated Piston Type Pumps in which body of the pump is used as the reservoir. On operating the handle piston gets actuated thus discharging the oil under pressure through outlet. These pumps are provided with check valve at suction and the relief Valves is provided to Safe Guard the pump from overloading. The models are given below :-

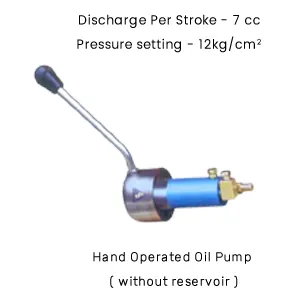

Model : H-7

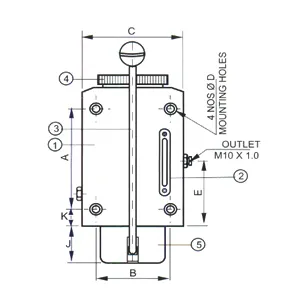

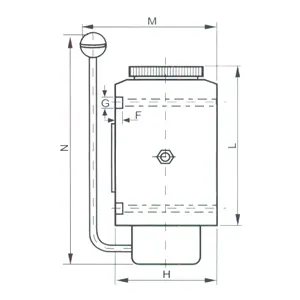

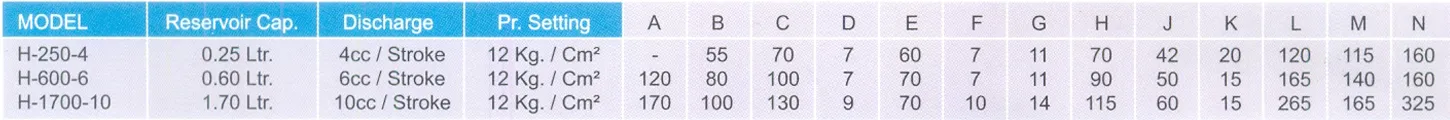

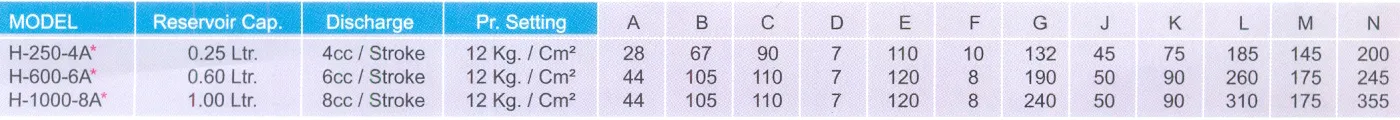

Model : H-250-4, H-600-6, H-1700-10

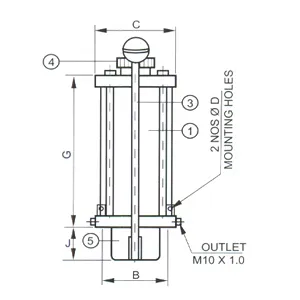

Model : H-250-4A, H-600-6A, H-1000-10A

Outlets on right side unless specified.

- Reservoir

- Oil window

- Handle

- Top cover

- Bottom cover

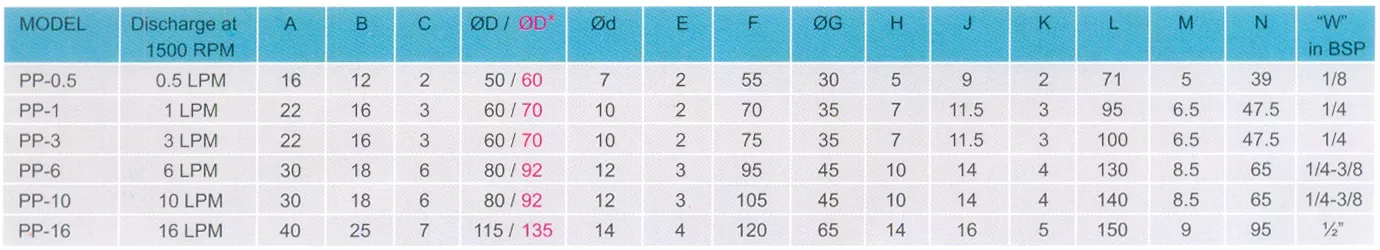

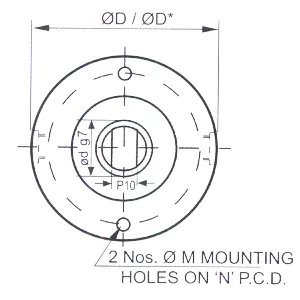

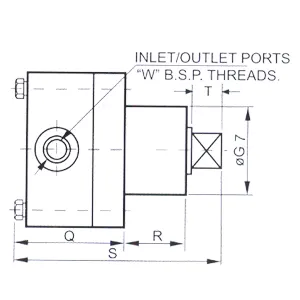

Rotary Operated Oil / Grease Pumps (Rotary Gear Pumps)

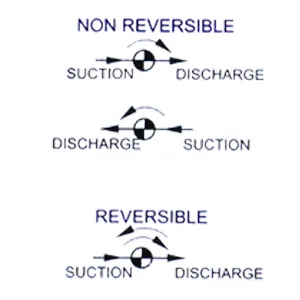

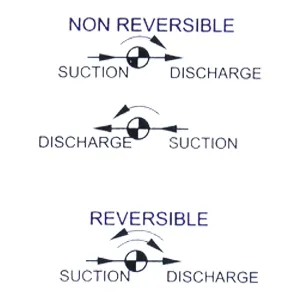

Rotary Operated Oil / Grease Pumps are Gerotor Type Pumps with positive displacement of oil. On the basis of construction they are of two types, flange type and insert type. Function wise these pumps can be classified into two types non reversible and reversible. Non reversible pumps are rotates only on one direction indicated by an arrow where as the reversible pumps are rotates on either direction, clock-wise and anti-clock-wise.

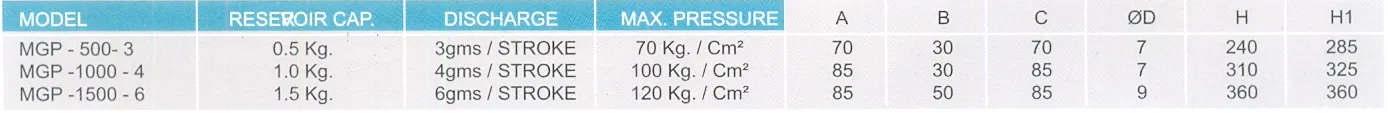

Pneumatic Grease Pumps / Systems

The Pneumatic Oil, Grease Pumps / Systems is suitable for dispensing of Grease & Automatic feeding of grease to bearing and other moving parts of machines. Such as Milling Machines, Rolling Machines, Presses & Hammers, Rubber Processing Machines, Dye Casting Machines, Furnaces etc. This pump is suitable for grease upto NLG-2. For distribution we used progressive blocks through this pump.

Pneumatic Grease Pumps are operated through pneumatic line, connected to the ports of pneumatic cylinder. The cylinder is built in with the pump housing. During on period of the pneumatic line a piston inside the cylinder is pushed ejecting out grease from the outlet port of the pump housing. During the reverse flow of pneumatic line grease is sucked through the suction port. In the pump spring force through follower plate exerted on the top surface of the grease make the suction of the grease positive & easier. Pneumatic Pumps is available in adjustable discharge & multiport with adjustable discharge in each port. Discharge & reservoir of pump is available as per customer requirement.

There is a reservoir mounted on the pump body for storage of grease. A tell tale rod connected for sensing grease level. Check valve is fitted on the outlet port of the pump to stop reverse flow of grease into the pump through outlet port. To bleed air entrapped in the system, there is a plug on the pump body which is to be opened till continuous flow of grease starts coming. The adjusting screw is provided in order to vary in output of the grease by tightening the screw the output of grease decreases and vice versa. It is must to put filter regulator unit in the pneumatic line fed to the pump. This will ensure that pneumatic line going to the pump is dust and moisture free.

For Air Removing, un screw the bleed plug apply compressed Air & Press the grease pusher by knob till grease come out from bleed port and plug the bleed port. The pump is ready for operation.

Manual Operated Oil / Grease Systems / Pumps

These are Manually Operated Piston Type Grease Pumps Which are used for Grease Lubrications. The grease is injected to the Lubrication points under pressure by these pumps.

- Pump Body.

- Outlet Port-1/4" BSP.

- Grease Filling Nipple.

- Bleed Plug.

- Lever.

- Reservoir.

- Top Cover.

- Tell Tale Rod Assy.

- Catcher.

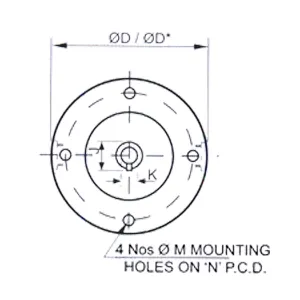

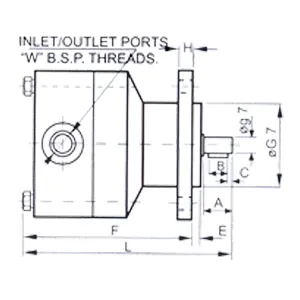

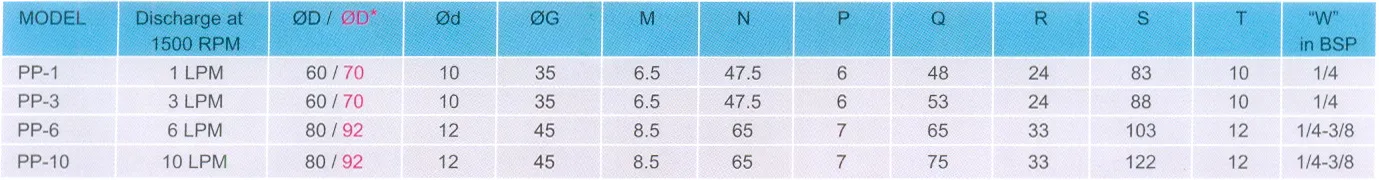

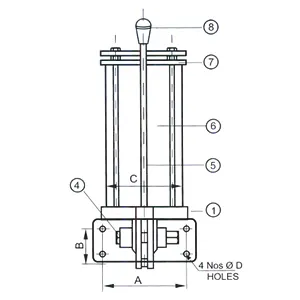

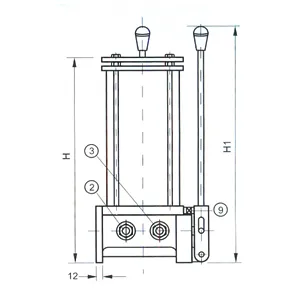

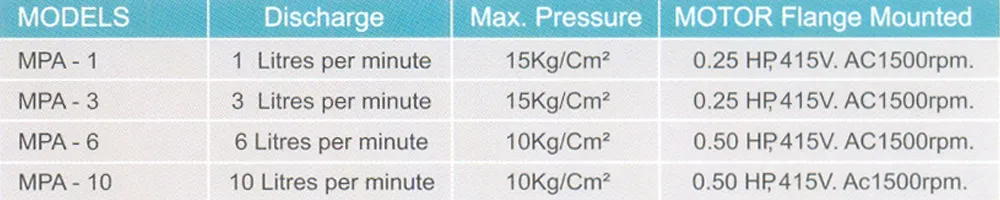

Motor Pump Assembly

Motor Pump Assembly is used for oil lubrication especially where continuous and high dosage of oil is required. It is also applied under Oil Circulation Systems. It is used almost in all machines where free flow of oil is required. The different specification is available with different model. It can suck the oil from 2 ft. downwards and circulate the oil up to 10 ft. height. The rotation of motor pump assembly is indicated on the label. Four mounting holes are provided to mount the system. An electrical terminal box on the surface of the motor is provided for connection.