Automatic Oil / Grease Lubricators, Automatic Lubrication Systems / Pumps

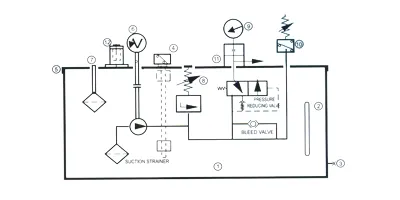

Automatic Oil / Grease Lubricators, Automatic Lubrication Systems / Pumps are the system which gets operated automatically as the same are controlled by Electronic Timer / Controllers. In these Systems Rotary Pumps is coupled with motor, when the motor starts there is a positive displacement of the Rotary Pumps which discharge the oil in the lubricating line under pressure. The Systems are provided with Pressure Relief Valves / Bleed Valves / Pressure Switches / Float Switches / Oil Level Gauges / Pressure Gauges / Oil Filler cum Air Breather / Suction Strainer. There are following Models :-

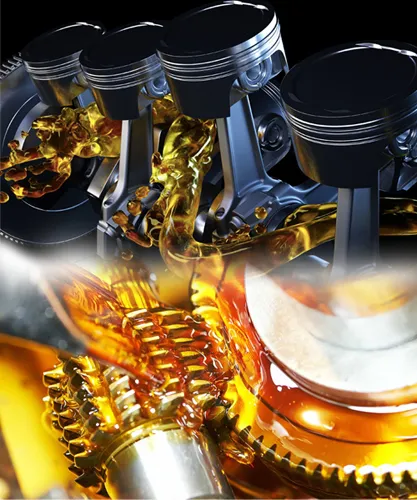

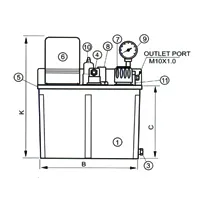

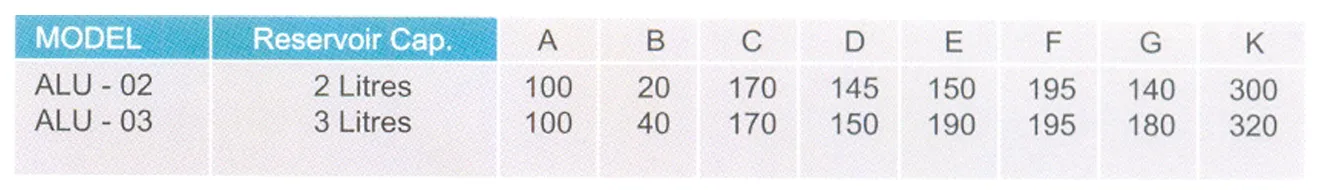

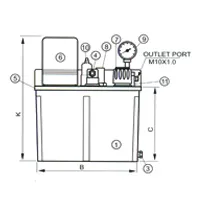

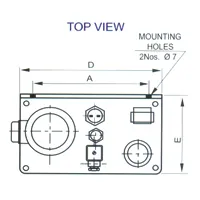

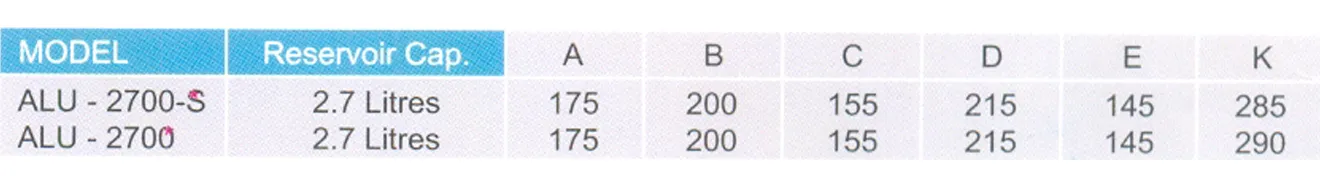

Model: ALU-20 /ALU-30

- Reservoir

- Oil Level Gauges

- Drain Plugs

- Float Switch

- Top Plate

- Motors

- Oil Filler Cure Breather

- Relief Valves

- Pressure Gauges

- Pressure Switch

- Junction Blocks

- Return Line Filters

Note : All these unit suitable for oil with viscosity range 50-1000 cst. Unit with vertical float switch is also available on customer request.

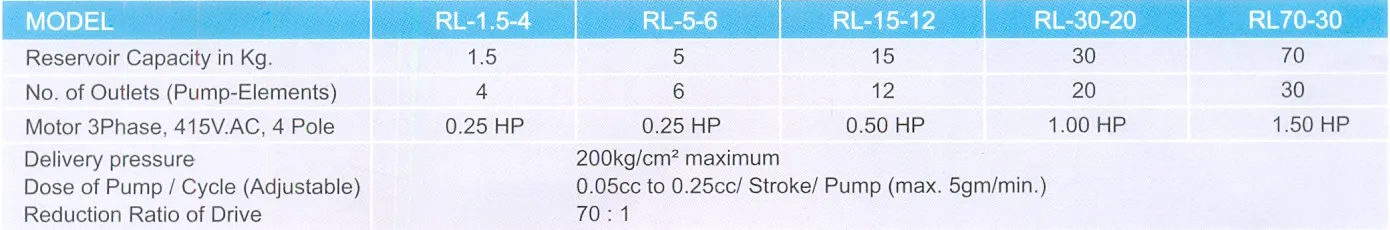

Dual Line Grease Lubrication Systems / Pumps / Machines

Dual line Lubrication Systems is used where large distance in lubrication points. This is high pressure pump and used in Steel Plants, Cement Plants, Turbine Generators, Furnaces, Sugar Plants, Sporang Iron plants etc.

Dual Line Lubrication Systems comprising of a single pumping station having pumping elements and fitted on the outer periphery of the housing. Reservoir also mounted on housing and fitted on base plate with Motor, Gear box, Change over valves, Pressure Gauges etc.

Dual Line Grease Lubrication Systems can be installed with a decided scheme by using Main pumping Stations, End Pressure Relay, Relief Valves, Change Over Valves, Dose Feeders, Inline Filter, Tubing & Fitting and Electronic Control Panel. When Pump Starts, then grease will deliver to main line and it will finally reach to connected lubrication points through dose feeder (Blocks). Once grease has delivered to all points connected with one line, the pressure will rise in the corresponding line as pump is still suppying grease. As soon as pressure crosses set pressure value pressure reversing valve, through control panel actuates. Grease starts flowing into second line. Delivery of grease to lubricating points take place and pressure rised again. When it crosses set pressure of end relay, the system will stop. Cycle is over and it confirm lubrication to all points. Now after preset 'OFF' time system starts again and repeats the same process.

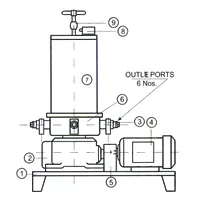

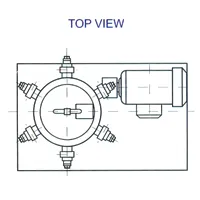

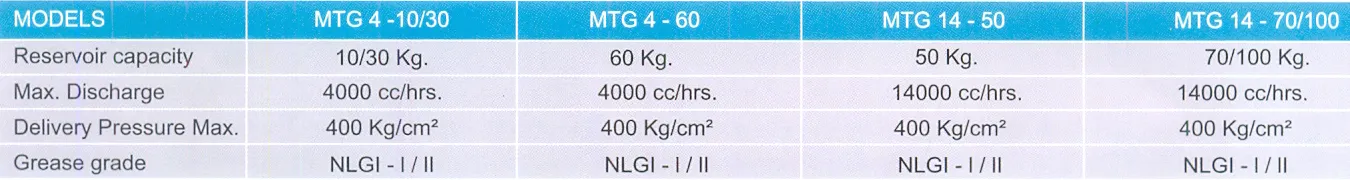

Multiline Radial Lubricators / Lubricating Systems / Pumps / Machines

The Radial Lubricating Systems is used for ejecting predetermined lubricant whether it is soft grease or thick oil under pressure to different points of the lubrication. The system is best suited for machinery such as Cement Plants, Sugar Plants, Textile Plants, Rubber Processing Plants, Chainsaw machines, Presses and Hammers.

Grease filling in the reservoir can be done manually as well as with the help of other pump. For pump 1/4" BSP port is provided on reservoir.

- Always use proper & clean Lubricants. Avoid foreign particles in the pump. The foreign particles or dust items are the main responsible factor to damage physical components of the pump and chocking in the plunger body. Do not plug out put of any pumping unit.

- Always fill the lubricants before it is empty to avoid air in the pump. The presence of air may be resulted in improper quantity of discharge.

- Base Plate

- Motor

- Reservoir

- Gear Box

- Gear Coupling Box

- Limit Switch (Optional)

- Plunger Pump

- Pump Housing

- Tell Tale Rod (Optional)

In this Lubricator outlets and reservoir is met as per customer requirement.